Boosting Food Safety Practices: Visibility and Practicality with Tip Jar #4

When it comes to food safety in any restaurant or food service environment, the priority is always clear: keep things clean, safe, and streamlined. While this might sound simple, executing it daily can be more complex. That’s why this tip is here to break down a few critical concepts that can help enhance food safety protocols, especially in relation to the equipment you use every day, like your ice cream machine.

1. Visibility – If You See It, You’re More Likely to Do It

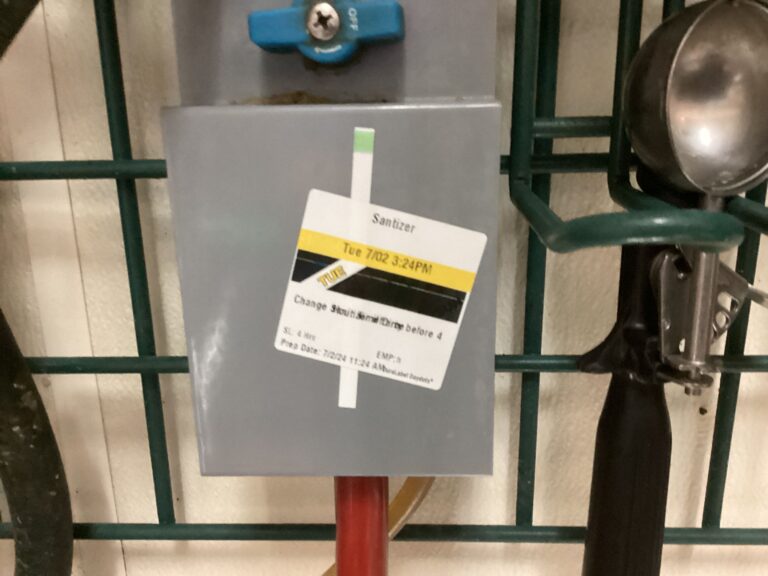

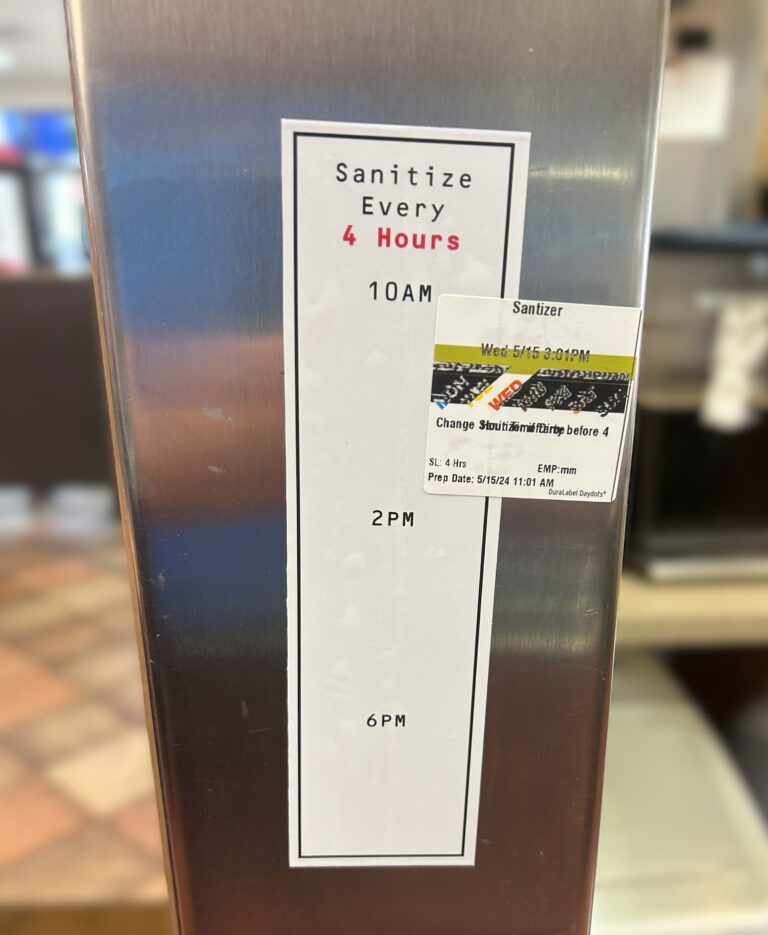

Take a look at your ice cream machine (like the Taylor model in the photos). You’ll notice clearly marked labels that are highly visible and easy to understand. These labels highlight sanitization schedules and critical times for maintenance. This visibility is key—it serves as a constant reminder for team members, making it more likely that they’ll carry out tasks on time. It’s a subtle nudge in the right direction, ensuring that food safety protocols aren’t overlooked in the hustle and bustle of a busy kitchen.

2. Simplicity – The Easier the Tool, the Better the Compliance

Simplicity is crucial for maintaining food safety standards. When the tools and instructions are straightforward, there’s little room for error. The Taylor ice cream machine features clear, easy-to-read stickers that outline the specific times and steps needed for sanitization and maintenance. This simplicity in instruction is a massive win for your team—they can easily comprehend and follow the guidelines, ensuring compliance and safety without feeling overwhelmed.

3. Ease of Use – Quick Processes Lead to Better Execution

The best food safety tools and processes are those that integrate seamlessly into daily operations. The more intuitive and accessible the process, the more likely it is to be followed consistently. The stickers on the ice cream machine are positioned right at eye level, making it easy for staff to see and understand what needs to be done. The simpler the step, the quicker it gets done—keeping safety top of mind and operations running smoothly.

4. Practicality – A Tool that Fits the Real Needs of the Team

The effectiveness of any tool or process depends on its practicality. Ask yourself: Does the tool make sense for the situation? In this case, the sanitization reminders fit seamlessly into the workflow of maintaining the machine. It’s about making food safety practical, not just another “to-do” on a long list. The design and placement of these reminders serve the real-world needs of food handlers, ensuring they meet cleanliness and safety standards without disrupting service.

5. Flexibility – Adapting to Better Ideas and Needs

Lastly, it’s important to be flexible and open to change. When new ideas or technologies arise that can make your processes safer or more efficient, be ready to adapt. The setup shown in these images is designed to be adaptable, ensuring that your team can easily adjust processes when necessary without compromising food safety. A good food safety company will focus on your specific needs and adjust tools, processes, and procedures to help you achieve the best results.

At Safer Plates, It’s All About You

At the end of the day, our goal is to support your unique needs—not to impose a “one-size-fits-all” solution. By implementing visibility, simplicity, ease of use, practicality, and flexibility, we ensure that the food safety tools and systems are not just useful but truly aligned with your operation. We’re here to create opportunities for your success by adapting to your needs and making food safety a practical and manageable part of your daily routine.