Tip Jar #6: Product Temperatures, Lids & Inventory Levels

When was the last time you walked into your restaurant with full confidence that every product’s temperature was compliant? Better yet, when was the last time you even thought about product temperatures? Whether it’s proper cooling, holding, or storage, maintaining correct product temperatures is critical to food safety.

So, how do you ensure consistency? Have you implemented steps to keep product temperatures in check? Can your team explain the procedures they follow and the visual indicators they use to confirm everything’s running smoothly? In this post, we’ll break down key strategies to maintain compliance and keep your food safety plan airtight.

Key Takeaways

- Proper assembly and cooling ensure safe product storage from the start.

- Correct product levels in holding avoid overcrowding and promote even cooling.

- Lids and time controls are simple tools that make a big difference in maintaining temperatures.

- Routine temping and documentation create accountability and ensure long-term compliance.

Proper Procedures for Managing Product Temperatures

1. Proper Product Assembly and Cooling

Start strong by focusing on proper assembly and cooling before products hit the stations. Rapid cooling processes—like shallow pans and ice baths—help prevent temperature abuse and bacterial growth.

2. Managing Product Levels in Holding

Holding too much product in a single station not only creates waste but also jeopardizes safety. Keep levels manageable to ensure products stay within safe temperature ranges.

3. Using Lids to Maintain Temperatures

Lids aren’t just for spill prevention. They’re an essential barrier that traps heat or cold, keeping temperatures steady during service. Train your team to use them consistently.

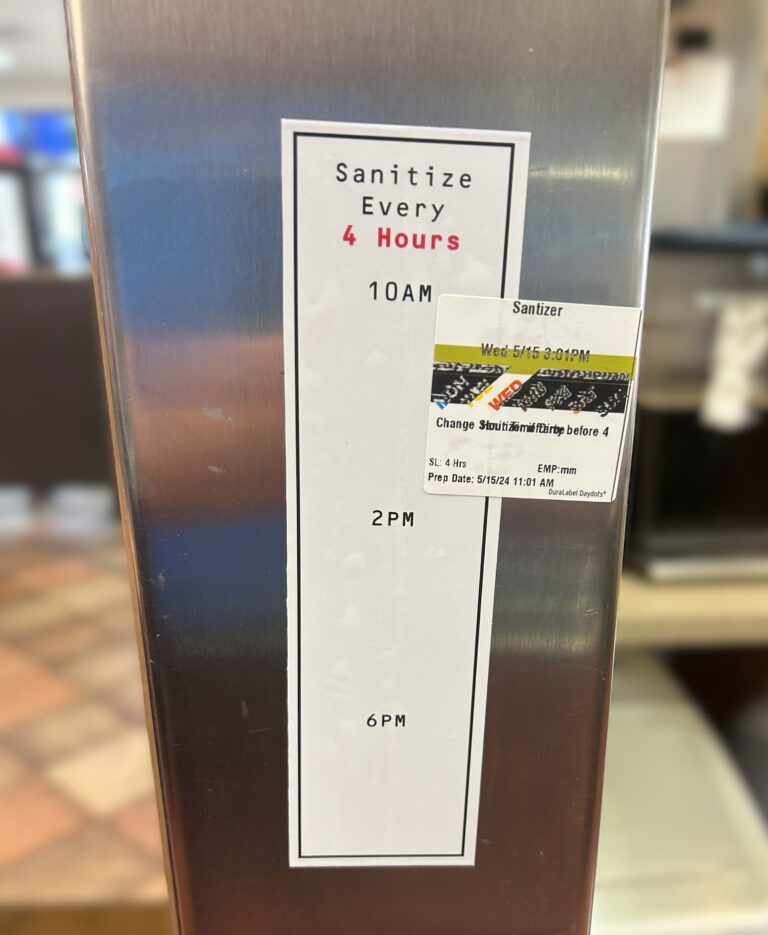

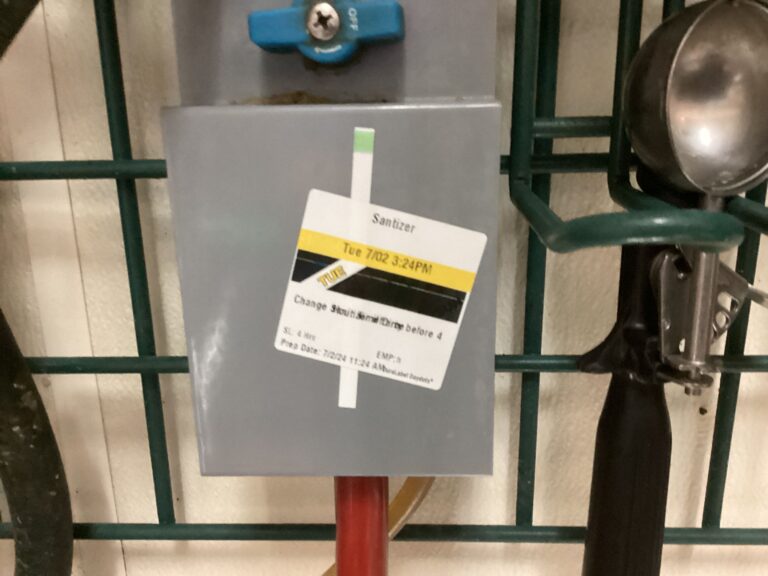

4. Product Rotation and Time Controls

First in, first out (FIFO) isn’t just an inventory mantra—it’s a temperature safety strategy. Combine rotation with time controls to limit exposure to unsafe zones.

5. Monitoring Refrigeration Equipment

Faulty refrigeration can undo all your hard work. Regularly inspect and service refrigerators to ensure consistent cooling and address any out-of-compliance temperatures immediately.

Handling Out-of-Compliance Temperatures

What happens when something’s off? Your team should know how to act swiftly. Establish a protocol that includes:

- Removing affected items from circulation.

- Investigating the cause of the issue (equipment, holding process, etc.).

- Documenting the incident and corrective actions for accountability.

The Importance of Documentation and Routine Checks

Routine product temperature checks should be a non-negotiable part of your operation. Use digital or paper logs to track results over time, ensuring accountability and uncovering trends that might need adjustment.

Clear labeling and proper documentation don’t just keep you compliant—they empower your team to own the process and address potential issues proactively.

Conclusion

Maintaining proper product temperatures is more than a checkbox on a food safety list—it’s a foundation of running a safe and efficient operation. By implementing clear processes, training your team, and holding everyone accountable, you’ll ensure your kitchen is always ready for success.

What steps can you start improving today? Let us know in the comments or share this Tip Jar with a colleague who could use a refresher on food safety best practices!