Safer Plates – Tip Jar #2: Ensuring Food Safety: Documentation and Accountability for Sanitizer Test Strips

In the hustle and bustle of a busy restaurant, maintaining food safety protocols can sometimes feel like an uphill battle. There are so many moving parts—staff are juggling multiple tasks, and unexpected absences can throw a wrench into the smooth operation of your kitchen. But no matter how hectic things get, ensuring that proper sanitization procedures are followed is non-negotiable. One crucial aspect of this is the consistent use of the correct sanitizer concentration levels, particularly when washing dishes or preparing fresh produce.

Let’s paint a picture: It’s another busy day, your veteran dishwasher is out sick, and your new hire is doing their best to keep up with the rush. As you breeze past the sinks, a thought hits you—did the new guy receive adequate training on testing the sanitizer water? Did they remember to use the test strips to ensure the concentration was correct before plunging into that pile of dirty dishes?

This is where a simple, yet effective, process of documentation and accountability comes into play. By using tools already at your disposal, you can implement a system that ensures proper procedures are followed, even on the most chaotic days. Here’s how to do it:

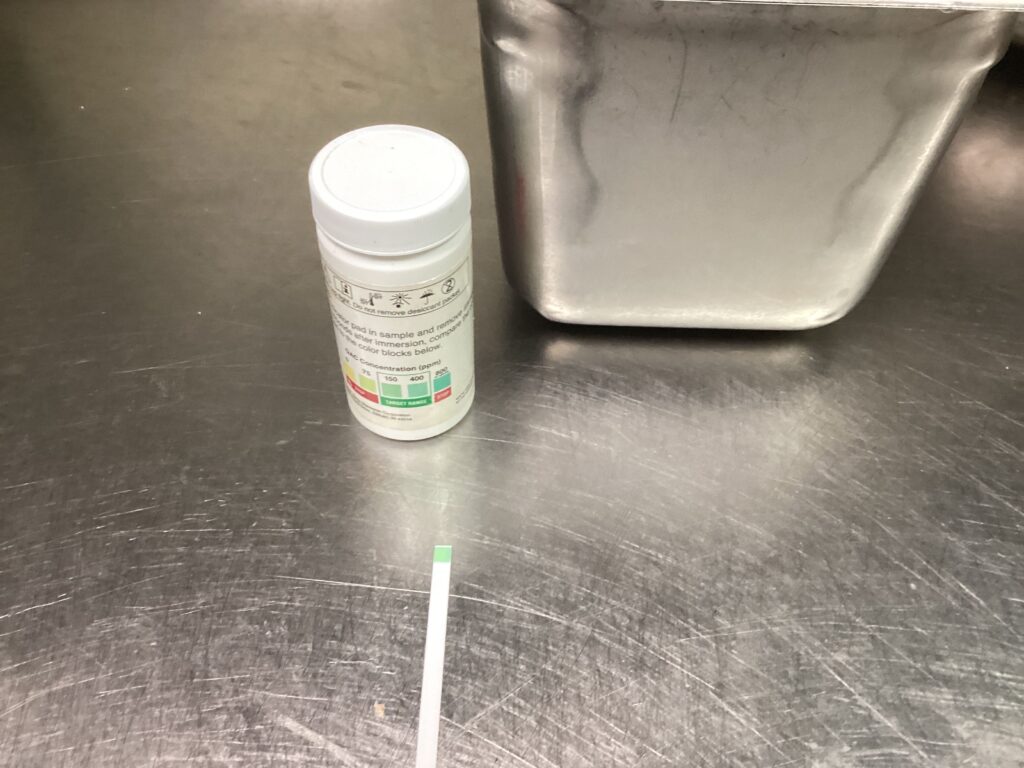

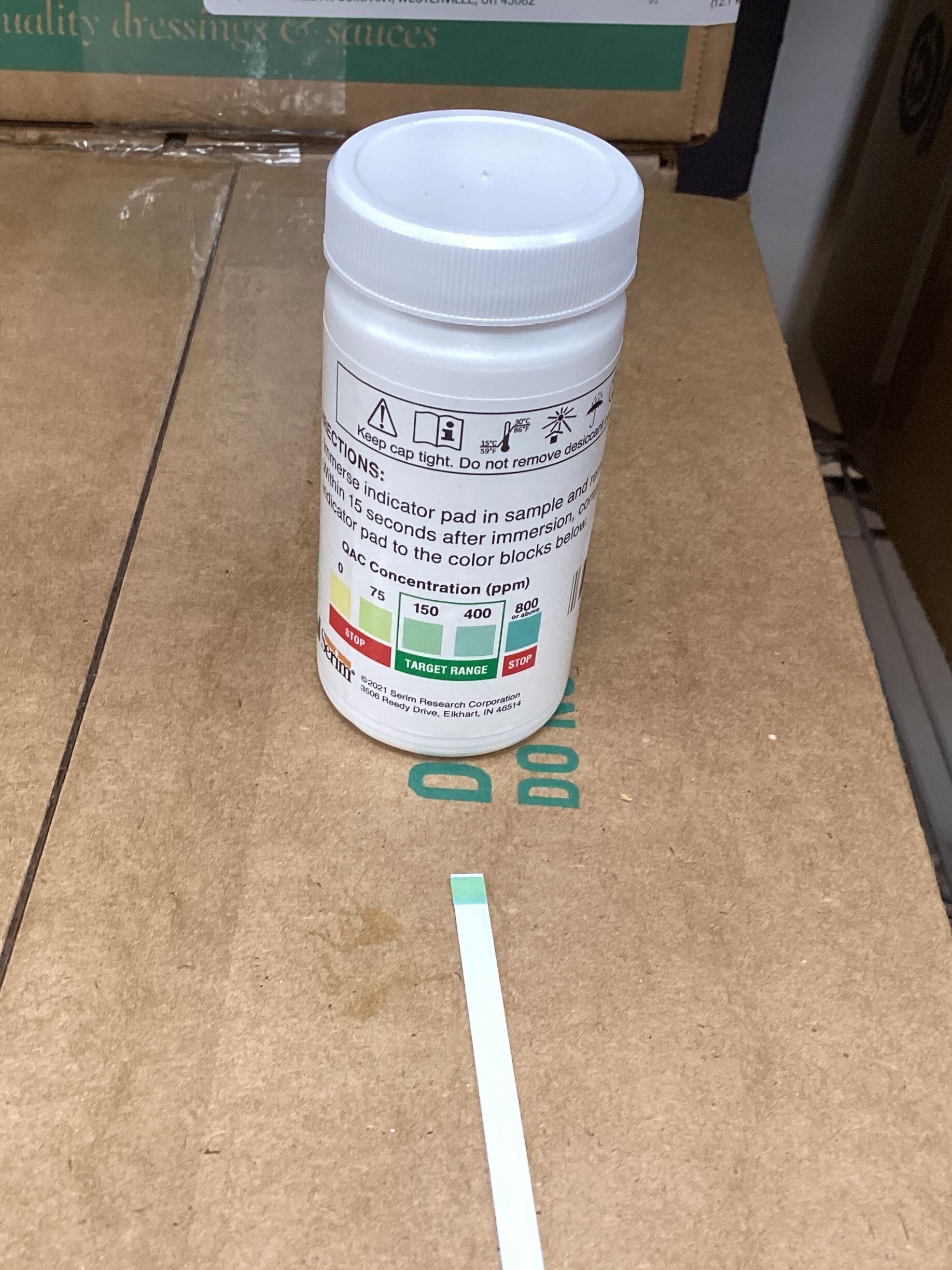

1. Use the Correct Test Strips

The first step is to ensure that your staff is using the appropriate test strips for the task at hand. Whether they’re checking sanitizer levels for dishwashing or produce washing, it’s crucial that they have the correct strips. Misusing test strips not only leads to incorrect readings but also jeopardizes the safety of your food and your customers.

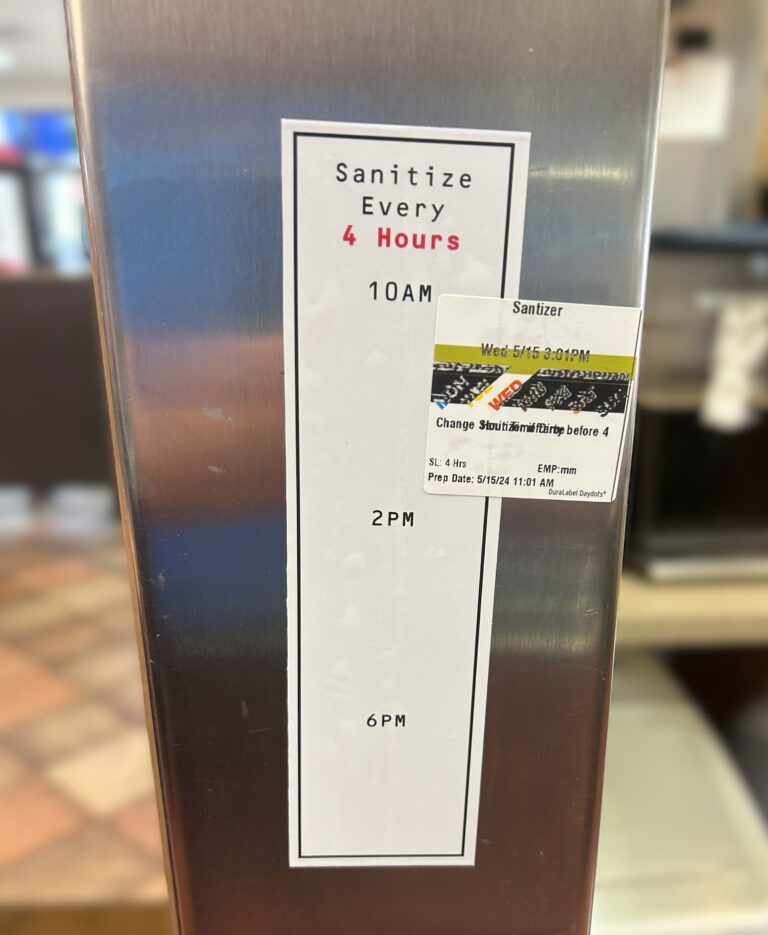

2. Print and Label

Next, print out a sanitizer food label that includes a 4-hour expiration. This label will serve as a timestamp, ensuring that the sanitizer concentration is checked and documented at the required intervals throughout the day.

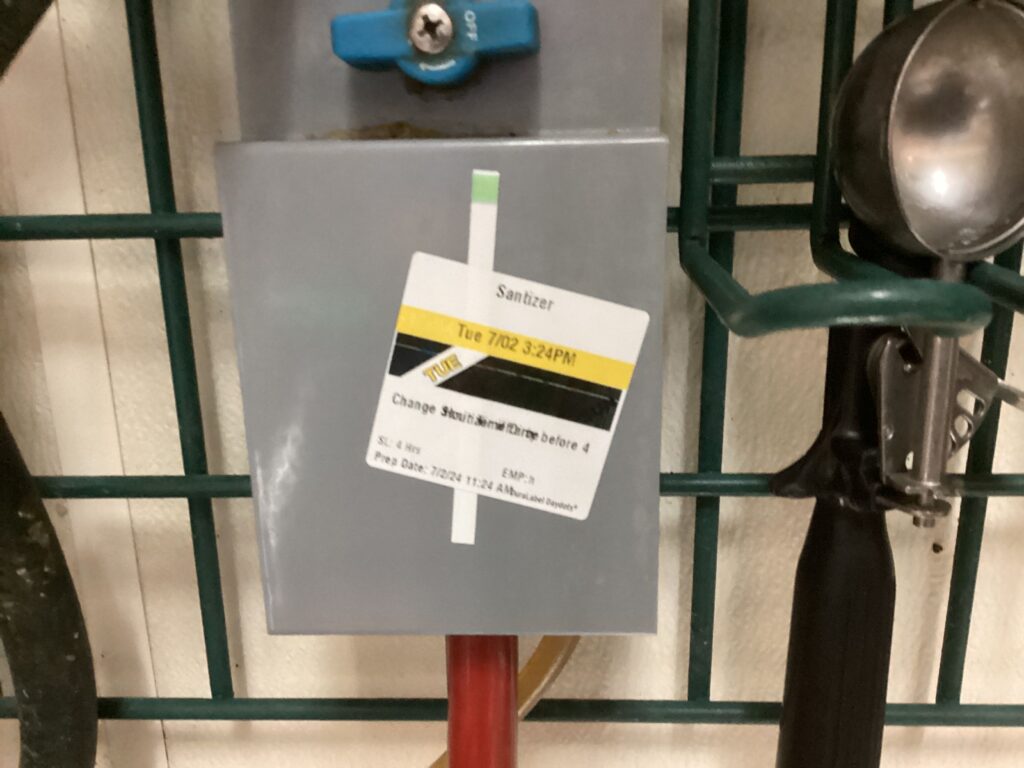

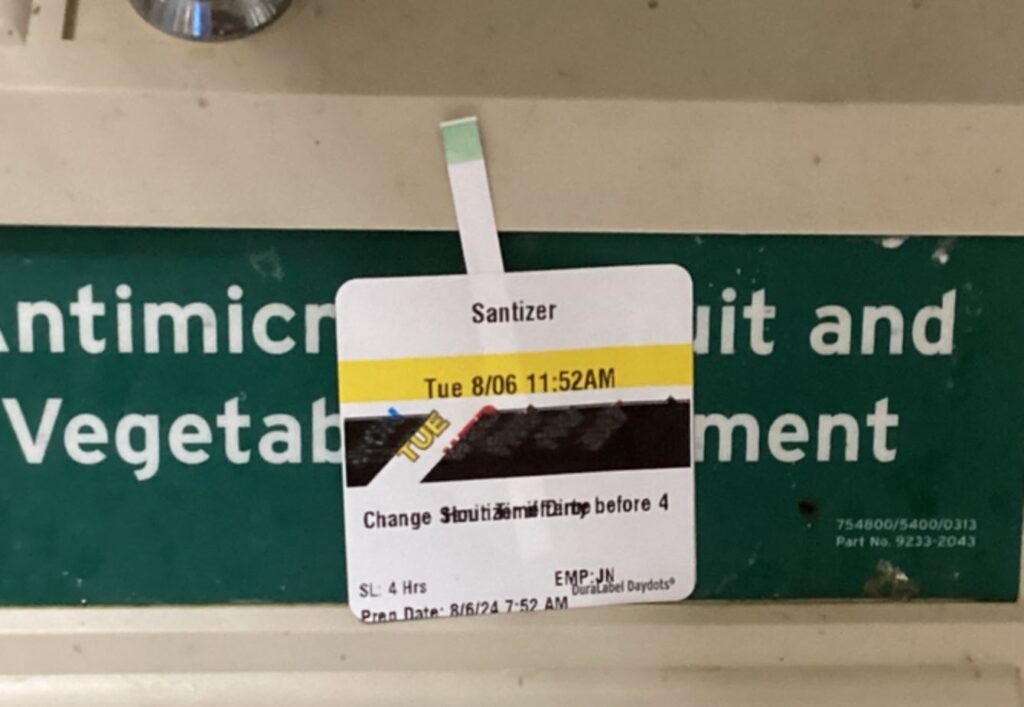

3. Mount the Test Strip

To make the process even more foolproof, mount the test strip on the sanitizer (or produce wash) dispenser above the appropriate sink. This not only makes the strip easily accessible but also serves as a visual reminder to your staff to perform the necessary checks before they start washing dishes or handling produce.

4. Document and Verify

And just like that—you’re done! This simple process creates a visible, documented, and verifiable system that tracks when the testing was done, what the concentration levels were, and who performed the check. This not only keeps your staff accountable but also provides peace of mind that your food safety protocols are being followed to the letter.

Why This Matters

Implementing this process ensures that there’s no more guessing (or hoping) when it comes to food safety. You’ll know with confidence that the proper steps are being taken to maintain safe concentration levels in your sanitizer or produce wash. This system also protects your restaurant from potential foodborne illness outbreaks, which can be devastating to both your reputation and your bottom line.

Food safety is everyone’s responsibility, and by putting these simple measures in place, you can make sure that it’s always a priority, even on the busiest of days. Plus, this documented process can be a lifesaver during inspections, demonstrating that you take food safety seriously and have the systems in place to back it up.

In the end, a little bit of foresight and preparation can go a long way in ensuring the safety of your guests and the efficiency of your kitchen. So, take the time to implement this process today—your future self (and your staff) will thank you!

Have more food safety tips or questions? Drop them in the comments below, and let’s keep the conversation going! Your kitchen can never be too safe. 🍴🔍