Tip Jar #7: Verification of Product Expiration Dates and Tracking Tools

Picture this: you’re hours into another busy day at your restaurant, juggling tasks when a guest complains about their “old-tasting” salad or “mushy” fruit. As you scramble to make it right—replacing the item, issuing a refund, or both—your mind races with questions. How did this slip through the cracks? Were expiration dates checked? Did anyone inspect the freshness of the products before opening? More importantly, could this be a food safety issue?

These scenarios are not just frustrating—they’re entirely avoidable. With the right systems in place and a culture that prioritizes food safety, you can eliminate these worries and focus on running a successful business. Let’s dive into how to systematize food safety processes, enabling your team to take ownership and ensure your customers always receive top-quality products.

Key Takeaways

- Food labels are essential for tracking product freshness and must be implemented thoughtfully.

- Updated labels throughout food preparation and storage processes help maintain consistency.

- Scheduled product reviews ensure regular quality checks and accountability.

- Job aids act as visual reminders, reinforcing tasks during shifts.

- Documentation provides a record for improvement and compliance.

Food Labels: Foundation of Food Safety

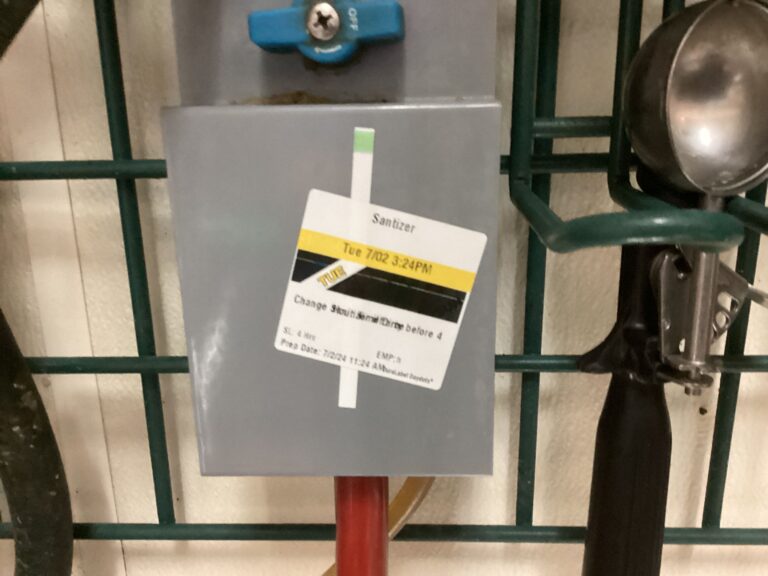

The first step toward a foolproof food safety program is selecting a reliable food labeling system. Consider these options:

- Handwritten labels: Simple but prone to errors.

- Food label printers: Efficient and accurate but may require an upfront investment.

- Third-party software: Comprehensive solutions that track and monitor food safety.

Once you decide on a system that fits your budget and operations, prioritize consistent training for your staff. The system is only as strong as the commitment of the people using it. Insist on strict adherence to ensure every product is correctly labeled every time.

Updated Food Labels: Tracking Product Movement

An effective food labeling system evolves with the products as they move through your business. Labels should transition seamlessly from bulk preparation to menu assembly and finally to storage and service stations.

By updating labels at every stage, your team can:

- Quickly identify gaps in processes.

- Address issues like mislabeled or expired items before they reach the customer.

- Improve overall workflow efficiency.

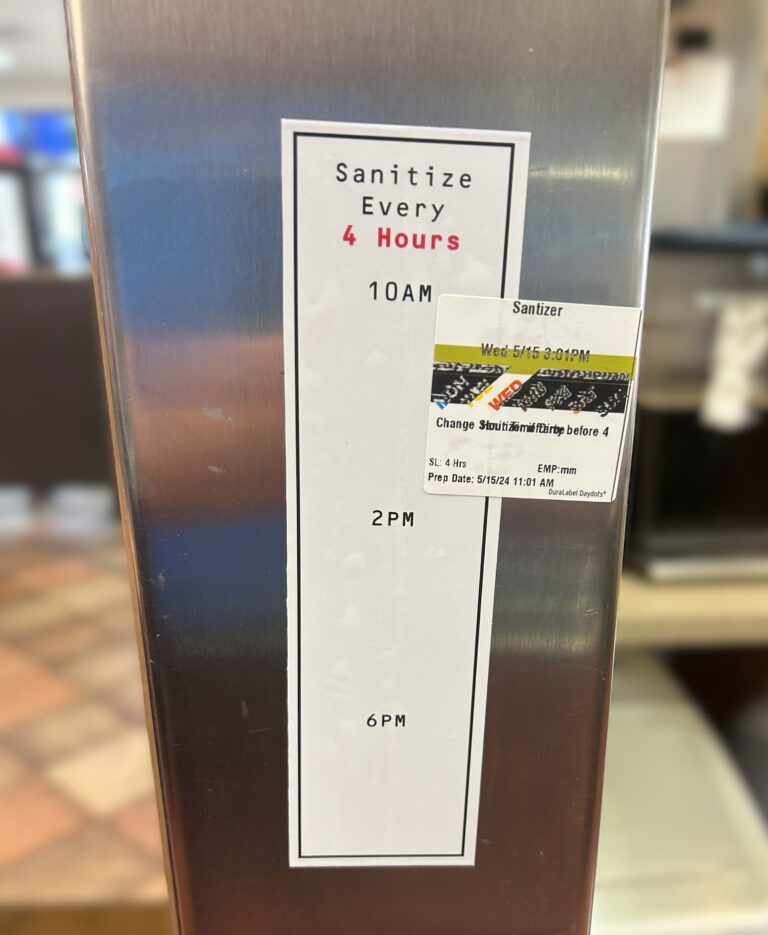

Scheduled Product Reviews: Regular Quality Assurance

How often are your products reviewed for freshness? Whether it’s twice a day or every few hours, the frequency should match the pace of your business. Regular reviews ensure no product goes unchecked.

Key steps for effective reviews:

- Assign specific times for reviews (e.g., pre-opening, mid-shift).

- Communicate expectations clearly to all staff.

- Establish a protocol for handling expired or sub-standard products.

Tracking reviews using logs or software ensures accountability and allows you to spot trends that need addressing.

Job Aids: Visual Reinforcement

Job aids are invaluable tools that serve as constant reminders for staff during busy shifts. Placed at each station, they should be:

- Clear and concise with step-by-step instructions.

- Visible to everyone at the station.

- Regularly updated to reflect any changes in processes.

These aids empower employees to stay on top of food safety tasks without requiring constant supervision.

Documentation: Record and Refine

Documentation is the backbone of a successful food safety program. Whether you use handwritten logs, digital systems, or software solutions, every review should include:

- The name of the reviewer.

- The time the review occurred.

- Details of the products and stations checked.

- Notes on any non-compliant items.

- Actions taken to resolve issues (e.g., adjusting production levels).

This information not only ensures compliance but also provides insights to refine your processes, improving efficiency and reducing waste.

Building a Comprehensive Food Safety Program

A robust food safety system hinges on these core principles:

- Clear communication: Everyone on the team should understand the importance of food safety and their role in it.

- Proper training: Equip every team member with the knowledge to execute their tasks confidently.

- Scheduled reviews: Build routine checks into daily operations to catch potential issues early.

- Thorough documentation: Keep detailed records to identify patterns and drive continuous improvement.

- Accountability: Ensure every staff member takes ownership of the program’s success.

Effective food safety practices are not optional—they are essential for protecting your business and reputation. By implementing a comprehensive system for product labeling, regular reviews, and thorough documentation, you’ll free yourself from the stress of potential food safety mishaps.

With these processes in place, your team becomes empowered to maintain high standards, and you can focus on growing your business. Food safety isn’t just a box to check; it’s a foundation for long-term success.

FAQs

How often should food labels be updated?

Food labels should be updated at every stage of product handling—from bulk preparation to final storage. This ensures the accuracy of expiration dates and minimizes waste or risk.

What’s the best way to train staff on food safety systems?

The best training programs combine hands-on demonstrations, job aids, and periodic refreshers to reinforce protocols and ensure consistency across shifts.

Are handwritten food labels still effective?

While handwritten labels can work, they are prone to errors. If your budget allows, consider investing in food label printers or software for improved accuracy and efficiency.

What should I do if I find expired products during a review?

Expired products should be discarded immediately, and the issue should be documented. Use this data to adjust inventory or production processes to prevent future occurrences.